How to choose the right food vacuum bags?

Did you know that vacuum bags are the most important factor in the quality of stored food? If you noticed that your vacuum bag melted during vacuuming with vacuum sealer or the machine didn’t remove enough air, then the problem lies in vacuum bags you are using and not in the machine as most users think.

Read the following post about the most important cues when you are vacuum-packing food for freezing and long-term storage.

What’s the best food vacuum bag like?

Three factors are important for determining the quality of vacuum bags:

- materials bags are made of,

- the thickness of the layers and

- ribbed profile.

Materials

Bag structure is very important because the insides of the bags are in direct contact with food. Bag producers need to guarantee all the used materials are food grade and list the temperatures, at which vacuum bags are safe to use (are the bags appropriate for freezing and Sous Vide cooking?).

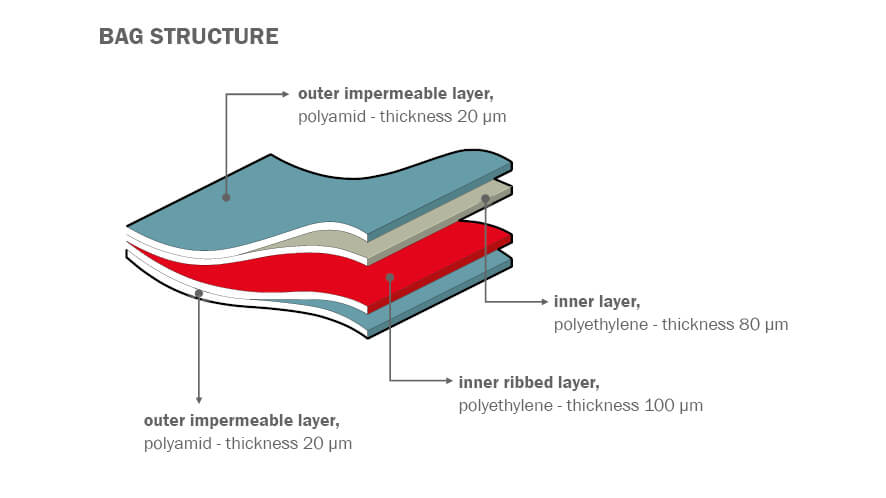

Status food vacuum bags are made of polyamide and polyethylene. Polyamide (PA) ensures oxygen impermeability. It is important to note that Status vacuum bags have the thickest layer (20 µm) of PA on the market. Polyethylene (PE) ensures quality sealing. Latest researches also show that PE is one of the safest materials to be used with food. Your food will stay the same as it was on the day of vacuum packing after six months or even longer. Bags can also be used for freezing and Sous Vide cooking (at 70°C up to 12 hours, at 80°C maximum of 6 hours, at 100°C maximum of 15 minutes).

The thickness

It is very important that food vacuum bags are thick enough because they also protect the food from outside mechanical damage. With the right bags, you don’t have to worry about food packages rubbing against each other in the freezer and tearing. Be careful when vacuum-packing meat with sharp bones. We recommend you coat the sharp edges with paper towels before vacuuming.

Status’s food vacuum bags have 100 µm thick smooth layer and 120 µm thick ribbed layer. More detailed information about the bag structure and thickness can be found in the picture.

Ribbed profile

The last two factors that distinguish top-quality vacuum bags from lower-quality bags are the shape and the height of the ribbed profile. Both are very important for efficient vacuuming – removing the air from the bag in many continuous cycles of vacuum packing goods. Let us elaborate: if you would try to vacuum pump the air out of the bag with two smooth layers, the layers would stick together even before all the air was removed and the food wouldn’t be stored properly. The special shape of the channels in the ribbed profile ensures effective air flow during vacuum packing. The height of the ribbed profile ensures quality vacuum storage in many continuous cycles of vacuum packing.

Vacuum foil made in Status has a special shape of ridges that was determined most efficient by many years of research. Their height is 0,2 mm and it ensured 50 and more quality continuous vacuum cycles.

How can you check the quality of the bags?

There are three ways to get information about the thickness of the bag and used materials – check the declaration, judge by price, or measure. The declaration should state the information about the thickness, but we still advise you to verify its truthfulness with the vernier caliper. If the declaration doesn’t state the information about the thickness and the bags feel thinner and are much cheaper than most vacuum bags on the market, they are probably not adequate for long-term food storage.

Our research department made an analysis of different brands of food vacuum bags. Send us an email to info@status.si for detailed information about research findings.

Why is it important to use top-quality vacuum bags?

The use of quality food vacuum bags is important for the mere process of vacuum packing and the protection of stored food.

Here are some of the most important advantages of storing food in the best food vacuum bags on the market:

- food doesn’t get an unpleasant aftertaste and smell of plastic,

- harmful substances don’t migrate into food,

- prevented oxidation and preserved the quality of the food,

- work well with all vacuum sealers,

- don’t tear easily,

- enable many continuous cycles of vacuum packing,

- EU-certified materials,

- vacuum bags are produced at the company’s premises in Metlika (Slovenia, EU) under the strict supervision of experts, who constantly improve the production process.

We recommend Status vacuum sealers and food vacuum bags and foil rolls for the best results when vacuum packing food.